-

Home

-

About Us

About Us

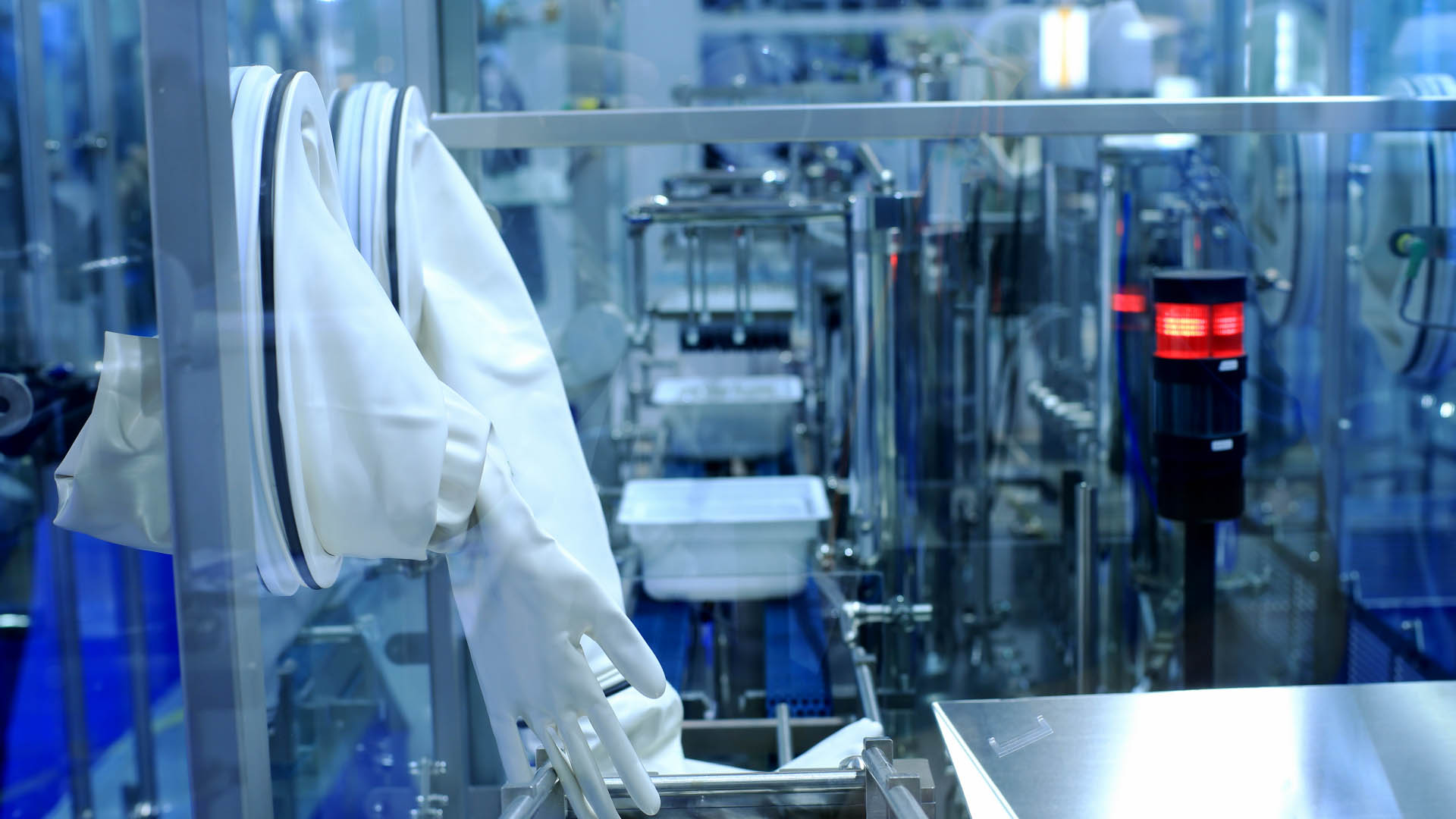

Founded in 2016, Dragon Sail Pharmaceutical Co., Ltd. is a high-tech enterprise focusing on antibody drug CDMO/CMO services.

More> -

Solution

About Us

Founded in 2016, Dragon Sail Pharmaceutical Co., Ltd. is a high-tech enterprise focusing on antibody drug CDMO/CMO services

More> -

News

-

Join Us

-

Contact Us

-

简体中文